Views: 0 Author: Site Editor Publish Time: 2025-04-24 Origin: Site

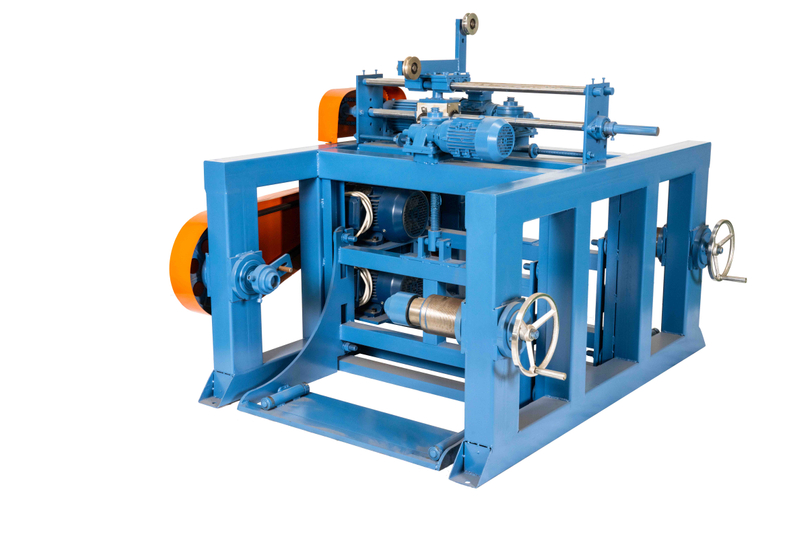

In the world of cable distribution and manufacturing, efficiency and precision are key. A Cable Spooling Machine is an essential tool used to manage and handle large volumes of cables. Whether it's for telecommunications, power distribution, or any other industry that relies on cables, these machines play a critical role in ensuring smooth operations. But what exactly is the function of a Cable Spooling Machine, and why is it so important?

The primary function of a Cable Spooling Machine is to help wind and unwind cables from spools or drums. This task might sound simple, but it is crucial for maintaining the integrity of the cables during transport and storage. Cables, especially those used in critical infrastructure, need to be kept in excellent condition to avoid damage, tangling, or degradation. The Cable Spooling Machine ensures that cables are wound evenly and securely, which helps protect the cables from issues like kinks or abrasions that can compromise their functionality.

Moreover, these machines also serve a vital function in the installation process. When distributing cables for large-scale projects, it's important to quickly and accurately deploy cables from their spools. An automated Cable Spooling Machine can handle this job with ease, saving valuable time and reducing manual labor.

Even Spooling and Unspooling: Ensures cables are wound and unwound uniformly to avoid tangling or damage.

Storage and Organization: Keeps cables organized and easy to handle during storage or transport.

Prevents Cable Damage: By using the machine, cables are less likely to suffer from physical damage that could affect their performance.

Faster Deployment: Speeds up the process of deploying cables on job sites, saving time for the workers involved.

RDEL is known for providing high-quality Cable Spooling Machines that are designed to optimize performance and efficiency. The company's machines are equipped with advanced technology that ensures the proper handling of various types and sizes of cables. Whether you're dealing with small, delicate cables or large, heavy-duty cables, RDEL's solutions are designed to meet your specific needs.

Precision Engineering: RDEL's machines are designed with precision in mind, ensuring that cables are spooled correctly, avoiding damage and maintaining quality.

Adaptability: These machines can handle a wide range of cable sizes and types, making them highly adaptable to various industries and applications.

User-Friendly: With easy setup and operation, RDEL's Cable Spooling Machines minimize downtime and enhance productivity.

Durable and Reliable: Built to last, RDEL’s machines are constructed using high-quality materials that can withstand heavy use over time.

RDEL's dedication to innovation and customer satisfaction has made their Cable Spooling Machines a trusted choice for cable distributors worldwide. Their machines ensure that cables are handled efficiently, reducing time spent on manual labor and increasing overall operational efficiency.

The benefits of using a Cable Spooling Machine go beyond simple convenience. These machines offer several advantages that can lead to significant improvements in business operations.

Spooling and unspooling cables manually can be a time-consuming and labor-intensive task. With a Cable Spooling Machine, the entire process becomes automated, allowing one operator to manage the spooling of large reels with minimal effort. This not only saves time but also ensures that the spooling is done consistently and accurately.

Improperly spooled cables are more likely to suffer from physical damage such as kinks, bends, or tangles. These issues can result in significant costs, as damaged cables may need to be replaced. A Cable Spooling Machine reduces this risk by ensuring that cables are spooled in a way that minimizes stress on the cable, thus prolonging its lifespan.

Although the initial investment in a Cable Spooling Machine may be high, it pays off in the long run by reducing labor costs and minimizing cable damage. The increased productivity and efficiency translate into lower overall operating costs. Furthermore, the time saved on manual spooling can be reallocated to other tasks, further enhancing business operations.

Manual cable spooling often involves lifting heavy reels and performing repetitive tasks, both of which can lead to workplace injuries. By using an automated Cable Spooling Machine, the physical strain on workers is significantly reduced, resulting in a safer working environment and fewer workplace injuries.

By keeping cables organized and evenly wound, a Cable Spooling Machine makes it easier to store and transport cables. This reduces clutter and helps prevent damage during transit, ensuring that cables are ready for installation when needed.

Cable spooling machines are used in a wide variety of industries, and they come in different designs to suit the specific needs of these industries. Some of the most common applications include:

Telecommunications: Cables used in telecommunications infrastructure need to be spooled and deployed with precision to ensure smooth installation.

Power Distribution: High-voltage cables require careful handling to avoid damage, and a Cable Spooling Machine is essential for managing these large cables.

Construction Projects: On large construction sites, quick and efficient cable deployment is necessary for various electrical installations, and spooling machines play a vital role in this process.

Manufacturing: In cable manufacturing plants, spooling machines are used to handle raw materials and finished products, ensuring that cables are wound uniformly and safely.

What is the purpose of a cable spooling machine? A Cable Spooling Machine is used to wind and unwind cables, ensuring they are stored in an organized manner. It prevents tangling and damage, making the process of handling cables much more efficient and secure.

How does a cable spooling machine work? The machine uses a rotating drum to wind and unwind cables. It typically includes a motor and tensioning system to ensure the cable is spooled evenly without any twists or kinks. Some machines are automatic, while others require manual operation.

Can cable spooling machines be used for all types of cables? Yes, Cable Spooling Machines are versatile and can be used for various types of cables, including electrical, telecommunications, and fiber optic cables. However, the machine needs to be adjusted to accommodate different sizes and weights of cables.

What are the advantages of using an automatic cable spooling machine over a manual one? Automatic Cable Spooling Machines offer several advantages, including increased efficiency, reduced labor costs, and more precise spooling. They eliminate the need for manual labor, minimizing the risk of errors and increasing overall productivity.

How does a cable spooling machine help prevent damage to cables? By ensuring cables are wound evenly and without excessive tension, a Cable Spooling Machine helps prevent physical damage, such as kinks, twists, or abrasions. This reduces the risk of cable failure and extends the cable's lifespan.

The Cable Spooling Machine is a vital piece of equipment for cable distributors, manufacturers, and other businesses that rely on cable handling. By automating the spooling and unspooling process, these machines save time, reduce costs, and ensure the proper handling of cables. RDEL’s advanced machines offer the perfect solution for businesses looking to optimize their operations and improve efficiency. Whether you're working with telecommunications cables, power distribution lines, or any other type of cable, a Cable Spooling Machine is an investment that can pay off in both the short and long term.

For more information on how RDEL’s Cable Spooling Machines can benefit your business, visit www.plugssolution.com.