Views: 0 Author: Site Editor Publish Time: 2025-04-25 Origin: Site

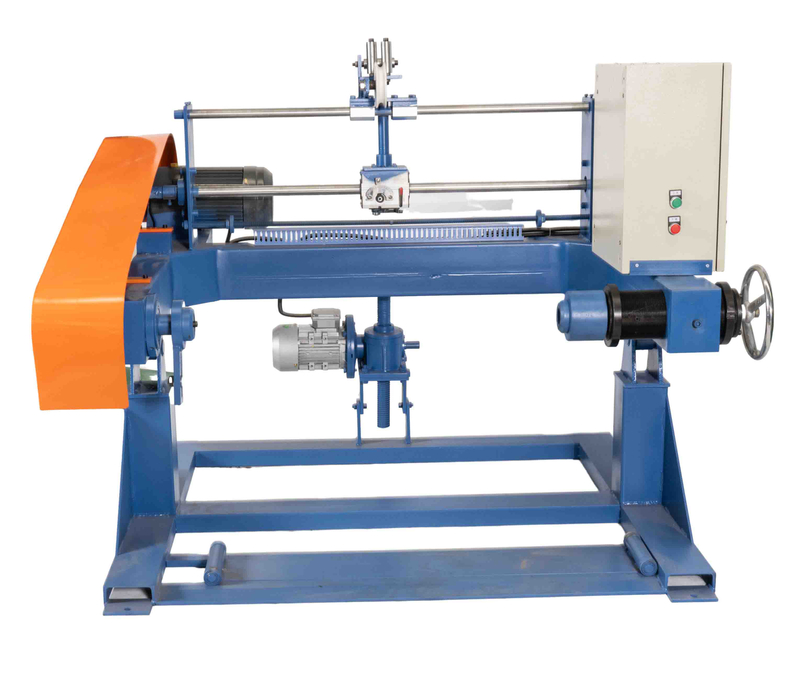

The cable manufacturing and distribution industry is undergoing a transformation. As with many other sectors, technology is driving change. Specifically, the integration of the Internet of Things (IoT) and smart automation is influencing how businesses handle cable spooling. The Cable Spooling Machine—a critical tool for managing large amounts of cables—is evolving to keep pace with these technological advancements. This article explores the emerging trends in cable spooling technology, particularly the rise of IoT and smart automation, and how these trends are shaping the future of the industry.

The Internet of Things (IoT) has revolutionized industries by enabling devices to communicate and share data. In cable spooling technology, IoT integration offers significant benefits, particularly in monitoring and optimizing the cable handling process. By incorporating IoT sensors and cloud-based systems into Cable Spooling Machines, operators can gather real-time data, improving their ability to track spooling performance, monitor machine health, and predict maintenance needs.

Real-Time Monitoring: IoT sensors allow operators to monitor cable spooling in real-time, providing insights into speed, tension, and alignment. This data helps ensure the cables are spooled correctly, reducing the risk of damage or wastage.

Predictive Maintenance: By collecting data on machine performance, IoT-enabled Cable Spooling Machines can predict when maintenance is required, helping prevent unexpected breakdowns and downtime.

Efficiency Optimization: IoT devices can track the overall performance of the machine, identifying inefficiencies or bottlenecks in the spooling process. This allows operators to make real-time adjustments to improve productivity.

The integration of IoT technology is driving a shift toward smarter, more efficient cable spooling operations. As IoT technology continues to evolve, the potential for smarter machines that can adapt to changing conditions and optimize performance in real-time is expanding.

Smart automation is another emerging trend that is making Cable Spooling Machines more efficient and effective. By incorporating advanced automation features such as robotics, artificial intelligence (AI), and machine learning, cable spooling machines are becoming more autonomous, reducing the need for manual intervention and increasing production capacity.

Reduced Labor Costs: By automating the spooling process, businesses can reduce their reliance on manual labor, which not only lowers costs but also minimizes human error.

Increased Throughput: Automated machines can spool cables at a faster rate and with greater consistency than manual methods, leading to higher throughput and faster production cycles.

Quality Control: With smart automation, Cable Spooling Machines can perform automated quality checks, ensuring that cables are spooled correctly every time, reducing waste and improving the quality of the final product.

Flexible Adaptability: These machines can adapt to a variety of cable types, sizes, and lengths, ensuring they meet the specific needs of each job without requiring complex adjustments or manual recalibration.

Smart automation represents the next phase in the evolution of Cable Spooling Machines, and its potential benefits are immense. By reducing human error, increasing speed, and enhancing quality control, smart automation is helping businesses achieve higher levels of productivity and efficiency.

RDEL is at the forefront of innovation in cable handling and spooling technology. With a commitment to providing high-quality Cable Spooling Machines, RDEL is continuously integrating the latest advancements in IoT and automation to ensure that its machines meet the needs of modern cable distributors and manufacturers.

IoT-Enabled Solutions: RDEL’s Cable Spooling Machines are designed with IoT integration, allowing real-time data monitoring and predictive maintenance to ensure maximum uptime.

Smart Automation: RDEL offers Cable Spooling Machines that are equipped with smart automation features to improve efficiency, reduce labor costs, and enhance production throughput.

Durable Construction: RDEL’s machines are built to withstand heavy use in demanding environments, ensuring reliability and long-term performance.

Customizable Features: With customizable options, RDEL can tailor Cable Spooling Machines to meet the unique needs of any operation, whether it's handling delicate cables or large industrial reels.

By embracing the latest trends in IoT and automation, RDEL is helping businesses improve their cable spooling operations and stay competitive in a rapidly evolving industry.

The integration of IoT and smart automation into Cable Spooling Machines has the potential to transform the way cable manufacturers and distributors operate. Here are some key ways in which these technologies are improving efficiency:

IoT integration allows businesses to track machine performance in real-time, identifying issues before they result in downtime. Predictive maintenance features ensure that machines are serviced proactively, reducing the risk of unexpected breakdowns and ensuring that production lines run smoothly.

Automation accelerates the spooling process, allowing businesses to handle more cable in less time. Automated systems can spool and unspool cables at faster rates, increasing throughput and reducing the overall time required to complete tasks.

With the continuous flow of data from IoT sensors, businesses can make informed decisions that improve operations. From optimizing spooling speeds to adjusting tension levels, the real-time data provided by IoT devices allows operators to make adjustments that maximize efficiency and minimize waste.

Smart automation reduces the need for manual labor, which not only cuts costs but also enhances safety. Operators are freed from physically demanding tasks, and with automation handling repetitive jobs, the risk of human error is minimized.

With the flexibility of IoT and automation, Cable Spooling Machines can be easily adapted to meet the unique requirements of different cables, industries, and projects. Whether dealing with delicate cables that require special handling or larger, more robust cables, automated systems can be configured to meet the specific needs of each job.

IoT integration in Cable Spooling Machines allows for real-time data monitoring, predictive maintenance, and performance optimization, leading to more efficient and cost-effective cable handling operations.

Smart automation speeds up the spooling process, reduces human error, and ensures consistent quality. It also enables machines to adapt to different cable types and sizes without requiring manual adjustments.

Industries such as telecommunications, power distribution, and manufacturing benefit greatly from IoT-enabled Cable Spooling Machines, as these sectors require precise, efficient, and reliable cable handling for large-scale operations.

Yes, many modern Cable Spooling Machines are designed to be customizable. With IoT and smart automation, these machines can be easily adjusted to handle different cable sizes, types, and lengths without requiring complex manual setups.

Predictive maintenance uses data collected by IoT sensors to forecast when a machine will need servicing. This helps prevent unexpected breakdowns, reduces downtime, and ensures that the machine operates at peak performance, saving time and money in the long run.

The future of cable spooling is being shaped by the integration of IoT and smart automation, leading to more efficient, cost-effective, and reliable operations. As Cable Spooling Machines continue to evolve with these emerging technologies, businesses can expect increased productivity, reduced labor costs, and enhanced performance. RDEL is committed to staying at the forefront of these innovations, offering cutting-edge solutions that help cable distributors and manufacturers meet the demands of a rapidly changing industry.

For more information about RDEL's innovative Cable Spooling Machines, visit www.plugssolution.com.